A Restoration Study

The oldest MOKUME GANE in JAPAN

Cultural assets at AKITA prefecture, Kozuka by Shoami-Denbei

5th Feb. 1963 Reserved

REPORT ON STUDY AND MAKING OF MOKUME GANE IN EDO ERA

12th May 2003

By Takahashi Masaki

The oldest MOKUME GANE in JAPAN

Cultural assets at AKITA prefecture, Kozuka by Shoami-Denbei

5th Feb. 1963 Reserved

REPORT ON STUDY AND MAKING OF MOKUME GANE IN EDO ERA

12th May 2003

By Takahashi Masaki

Mokume Gane is the name of a unique Japanese metal crafting technique which consists of layering different-colored metals, and painstakingly carving and forging them to create beautiful woodgrain patterns. This is a study of what is believed to be the oldest Mokume Gane work, a Kozuka knife in a gold and silver Mokume wood grain pattern signed by Shoami Denbei, manufactured by Shoami Denbei, residing in Dewa Akita.

This study takes a fresh look at these unique beautiful patterns that were a specialty of Denbei, focusing on the cause and effect relationship between the stacking and the processing method, and showing the manufacturing process..

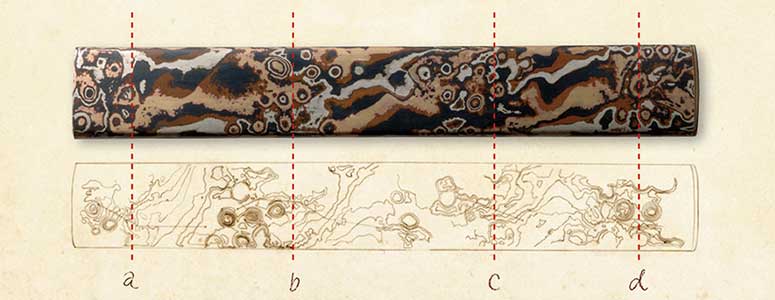

Mokume Gane is made by stacking a number of metal sheets on top of one another.A photograph of the Kozuka knife was enlarged and the pattern was traced and replicated in order to find out how many types of metal has been used and how they had been stacked.

The detail of the patterns on the “Akita prefecture designated tangible cultural property Kozuka knife – Gold and silver Mokume wood grain pattern signed by Shoami Denbei” is extremely fine. There are gradations evolving between the intricate materials, some within a framework of one millimeter square. In some parts, there are places where it is impossible to distinguish, and so the observations were carried out in places where the distinctions between the materials were clearly visible. A and D on the next page show these parts.

The technique of Mokume Gane consists of first carving down a metal stack, or billet, using tools such as a chisel, and then creating the pattern by using a hammer to forge it flat. By using this process, the order of the metal layers remains the same whichever portion is extracted to reveal the pattern on the surface.

Tracing result

Number of layers: 16

Materials (and number of layers): Copper (6), Shakudô (5), gold (3) and silver (2)

The results of the analysis following tracing of the Kozuka knife pattern

A:shakudo, gold, (copper), gold, shakudo, copper, silver, shakudo, copper, gold, shakudo, copper, silver, shakudo, A copper.

B:A copper, gold, shakudo, (copper), shakudo, gold ,copper, shakudo, silver, copper, shakudo, gold, copper, shakudo, silver, copper, shakudo, B(gold), shakudo, copper.

C:B gold, (copper), B gold, shakudo, copper, silver, shakudo, copper, gold, shakudo, C copper.

D:C copper, silver, shakudo, copper, gold, shakudo, (copper).

This chart shows several points where it was possible to extract clearly the difference between the materials. a is copper, b is gold, c is copper in the same layer.

It became clear, as a result of the observation, that the order of the layers was reversed at the boundary between the A portion and the B (copper) portion of the pattern.

It was verified through observation by comparing the trace drawing to the contour lines that this was not a simple reversal in the order of the layers that the metal layer before and after the displayed “copper” was the same layer.

This led to the thinking that, before creating the pattern, some sort of particular process was used so as to reverse the order of the layering in part.

Further observation of the C portion confirmed that the layers were reversed with (c) as a boundary and that, furthermore, these were in the same order of layering as the A portion.

It can be assumed from these results that the reversal in the layers is something that happens with regularity. A more detailed analysis of the close-up clearly showed that the reversal in the layers occurs alternately as original Mokume Gane patterns in segments of the streamline shape.

The order of the layering was determined to be the 16 layers of copper, Shakudô, gold, copper, Shakudô, silver, copper, Shakudô, gold, copper, Shakudô, silver, copper, Shakudô, gold, copper. It can be supposed that these metals were layered, forged into a billet, and then underwent a twisting process.

The results of the analysis show that after fours counts of twisting of the surface, the back, the surface and the back, the billet was then flattened using a hammer.

It is through this process that the twisted pattern that is at the origin of Shoami Denbei’s unique Mokume Gane pattern came up to the surface.Actual restoration work is being done based on the results of this analysis.

Those materials whichi I used this time, were chosen in consideration of the processing, it was assumed that K20 gold and 970 silver were used so that hardness might steady based on the pure copper.

It worried very much because of the decision of the size of the board material. If it is simple thing which carving accumualting with the tools like the drill and TAGANE, and it does humbly by forged processing., likeTakahashi sect’s Mokume Gane, it is possible to make a bigger size of Mokume pattern, so it is able to cut out the only a necessary part. But, the Mokume Gane of Dewa akita ju Shoami Denbei’s is impossible to make it bigger and cut it out because of the twist processing may add. So the size of the accumulating stage to decide the final finish size. It was clear for the area of surface, but this time, for the thickness, it was guessed from the pattern and decided. The depth of the carving of the ripple of the roughly concentric circle pattern was the standard for the guess. To be able to do the height difference too much in accumulating with the thickness, and to influence externals and streamlined pattern remarkably, so it was judged that the size of the thickness of Mokume Gane of finish is a very thin board material. Finally, it was assumed that it adjusted it at the stage forged to tabular while confirming the state of the pattern when the carving lowering was processed.

From the expectation size of completion and based on the law of mass preservation, and also speculat to the removal of the imperfect part at the edge after accumulation and the compression that add when the material is processed to a flat board material by using a hammer, then decided to product from the 7mm to 8mm accumurated corner stick. It is impossible to be settled at dimensions closely, because in character of Mokume Gane, there are many parts to depend on perception and the experience of a producer from the atmosphere of the pattern and the state of the laminating of matterial at that time, and also a difference of a few processes are making the influence to the pattern. I did a simulation many times by using the corner stick of copper before making actually. But above mentioned, in an acutual accumulation, it is forced to the flexible correspondence for the change of the material from various factors. Therefore, a final decision is a done only on work. On this technology, there is the situation continues that cannnot help to correspond flexibly at the very last moment. This time, all of the compression and extention processing are done by using the hammer, so it is possibole to adjust the rate of the extention for the vertical and horizontal direction. The corner stick selected the balance that was suited to do twist processing and estimate from the volume of the flat plate of finish.

At first I polish the each materials with #600, #800, #1000, #1200, #1500 of sandpapers which I prepared in turn, then after that, finished the surface uniformly politely using together with the charcoal polish. After that, repeat them in the turn of analyzed, then heat them then gave the forge welding processing. Mokume Gane is hard to be understood precisely by lack of information and complexity of the process and tends it to be told with welding or bonding, but closely, it is right of the expression of diffusion combination. When approaching the surface of metals for an atom level then give pressure,it makes a metalic bond happen. For a principle, it is possible to join two metalsv for coherence each other. Mokume Gane is the technique which based on the principle of diffusion combination, to conenect the different colored metals as a state of solid-phase body, with the means of heating, pressurizationIn brief, it is not a method of dissolving the metals for connect, but also the method of connecting in a solid state of metals. This technology is applied to production such as a drive part of cars widely industrially. Mokumegane is special metal processing technique which using this principal to be enabled by realizing combination to bear if it create a pattern without losing each metal original hue. After inspect the details and removed the incomplete part of laminating, give the forging process in the sape of a corner stick of 7mm from 8mm with a hammer.

By the trace analysis, the twist processing turns out four in total, reversals of the table, the back, the table, and the back. To give the heating and annealing over and over carefully about the order of accumulating, for making the 4 times reversal which mentioned above had happened th the forged molded corner stick. Then, give it to the twist processing carefully, little by little. Afterwards, forged molding was done to the corner cylinder shape again.

Above-mentioned, when the detail of the pattern was observed, it was able to be confirmed that more than half of the number of sheets of accumulating of the metals among the 16 layers, were the constitution elements ot the ripped patern. This means, after the twist processing was added, carving the depth of more than half of accumulating with the tools like the drill and tagane. To carve for the depth by this, at the accumulating with the thickness, it makes big influence on the external form of total and the pattern which was made by the twist prosessing, by the difference of the pitch when it was hitted with the hammer for makes it for flat. Accutually, it was not carving at once. The pattern was made from the twist processed corner stick which was processed to some extent to the flat boarded, which was done the processing of the carving and striking repeatedly over dozens of times. This time, the corner stick material that gave the twist processing was forged using the hammer until the thickness becoming a below about the half. On that process, originally, Mokume Gane is the technology that is not able to produce the same original pattern. But this time I worked very carefully and politely to bring it close to Kozuka by Shoami-Denbei’s as much as possible while using a loupe to confirming the depth of the carving of the drill and tagane. It makes a change for the pattern if using the kind of cutting tool such as file. So this time, I used the hammer until the very end of the completion, to make the surface uniformity, then it was assumed to finish which measered the timing for the pattern may become smooth when reaching the finished size.

This time I used the solution for coloring which consists form 3g of the copper sulfate, 3g of copper green rust, and a little of alum by the 1? of water which used in Tokyo University of Arts.c:B gold, (copper), B gold, shakudo, copper, silver, shakudo, copper, gold, shakudo, C copper. To fat removeing with baking soda, then puts the grated radish on, and puts it into the boiling solution for coloring. To check the color state, it is repeated to take it out and rub the surface with baking soda lightly, and puts the grated radish on, then take it into the liquid. To fine-tune the medicine by the color, it stews finally for about 20minutes, and it is colored. It quickly takes out in the liquid when becoming a good color, and it soaks it in to the water. Puts the beeswax on the surface for protection and for putting out gloss, then it complets.

Having carried out reproduction studies of works by Shoami Denbei and Takahashi Okitsugu, I have come to understand even better the depth of the unique metal working techniques of Mokume Gane, a craft of which Japan is proud on a global level. This study work was a precious experience for me, not just an opportunity to analyze the manufacturing process of the time, but also a way to experience what the craftsmen of the time felt. It also brought a renewed realization of the difficulties associated with transmitting the Mokume Gane meta engraving techniques.

Mokume Gane is by no means simple to transmit, from the difficulties in the process that lie in the details, the ambiguities of its particularities transmitted via oral traditions, and the fact that skill must be acquired in both carving and hammering as a given. And since much of the process is taken up by creating patterns, the artist needs further study in the various fields in order to refine what is being produced. Because of this, if there is only guidance from the more experienced, what is produced risks staying at the experimental level, with the risk of difficulties in transmitting the correct traditional techniques. Even slight changes in equipment or tools used by the creator will impact the fine aspects that greatly affect the manufacturing process, so that many of the people who toy with Mokume Gane techniques end up with only surface knowledge of the techniques, or nothing more than a practice run at manufacturing.

The subject of the spiritual perspective of Mokume Gane techniques was addressed by the late Professor Ito Hiroe of Tokyo University of the Arts in “On the Subject of materials – Through the Manufacture of Mokume Gane.” But along with the diversification of techniques in today’s society, it has also become more difficult to bring out the spiritual element in metal working techniques.

In the technique of Mokume Gane, the changes in the metal materials are felt with all five senses, and it is by communicating with the materials that the special patterns appear. And I felt a deep poignancy at the difficulty which even I, as an artist, had in understanding the spirituality embedded in this process. It is a great shame, within the framework of Japanese culture, only the uniqueness and the natural texture born of randomness are admired, and the appreciation does not go as far as the ideological and spiritual meaning of the Mokume Gane techniques born of the communication between the materials and the creator.

Through the experience of carrying out these reproductions, I was able to plunge myself into the sensibility of the creators of the period, slowly transcending the concept that “technique is the process of shaping materials” and coming to realize that “technique is a means for expressing yourself.”

When, however, I grasped the fact that “the process is not an act of expression but the act itself exists as expression,” I realized that it is “possible for technique itself to become expression.”

Lastly, when talking about Mokume Gane techniques, one must not overlook the significance of the ever-present uniquely Japanese aesthetic sensibility that “concentrates three dimensional space into a flat world.” My belief is that it is this special sensibility that led to the development in Japan of this unique metal-working technique called Mokume Gane. And the technique of Mokume Gane is in fact the concrete realization of this.

One could say that the designs and patterns that are created on the surface are all the impressions of these actions and a record of the process. The breathing of the creator at each step of the creation is captured as such, and the results exist as patterns. If anything, couldn’t one just say that Mokume Gane is a technique for recording, as impressions, the act of expression and the thoughts of the creator visually as designs and patterns? And then, these impressions would forever be felt by those looking at the pieces as “energy” locked with them. This would be, so to speak, a “record of the creator’s thoughts.”

Would this not be the reason why we are so captivated by this technique known as Mokume Gane?

Copyright(C) 2003-2005 Masaki Takahashi All Right Reserved.